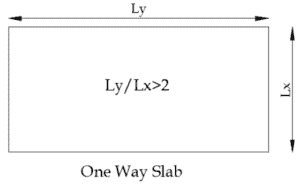

What is a one-way slab?

When a concrete slab is supported on all four sides and the ratio of long span to short span is greater or equal or than two, this means it’s a one-way slab. The load on the one-way slab is carried by the short span in one direction. However the main reinforcement bar and distribution bar in a transverse direction.

The formula of One-Way Slab: Longer span (Ly)/Shorter span (LX) ≥ 2

The behavior

The direction (shorter side of one-way slab) in which load is transferred is known as span. It’s is designed for the spanning direction by itself as it bends in only one direction.

The main tension reinforcing bars, therefore, run parallel (spaced uniformly) to the shorter span and are usually placed at the bottom of the slab.

In the longer direction, a minimum amount of reinforcement is provided to take care of the shrinkage and temperature and effects in that direction. This reinforcement steel is called the distribution steel or secondary reinforcement.

This steel also helps in distributing the load. The distribution of steel helps in distributing the load transversely over a larger width, thus offsetting the local effect like plastic shrinkage cracks due to temperature and shrinkage. Even when a slab is supported on all four sides, the behavior of slab is expected to be as a one-way slab only as evident from the deflection contour

Minimum Depth

Minimum depth of the one-way concrete slab, most of the times is governed by deflection criteria. Sometimes the minimum depth is adequate as per flexure design, but if deflection criteria aren’t fulfilled such slabs will face vibration even under small loads like walking, jumping, etc. Although even checking the design regularly may give you less depth, always check for deflection. Here you can provide marginally larger depth and can reduce steel to economize on the overall cost. Please note that the vibrations never give a feeling of the safe building to occupants.

Types of One way Slabs

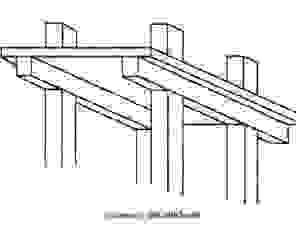

1- One-way Solid Slab with beams

This type of slab is supported on beams. Depending on beam and column arrangements, this system can be designed for wide ranges of the load conditions.

2- One-way Ribbed Slab with beams

One-way Ribbed Slab with beams is used for the office buildings (low rise), parking structures, and warehouses.

3- One-way Ribbed Slab with integral beams

The one-way ribbed concrete slab is provided with a greater span as compared to the concrete solid slab. The one-way ribbed concrete slab is economical when it’s used in the modular or prefabricated form.

4-One-way Slab with the Hollow Block

One-way concrete slab action is assumed in a ribbed slab with joist beams made of the precast double-tee section, in the ribbed floor with integral beams, and also in hollow-block or hollow-cored slabs.

Summary

- In practical, One-way is supported by only two parallel beams or walls.

- Main reinforcement(rft) is provided in one direction for one-way slabs.

- one way slab has structural strength in the shortest direction

- Deflected shape of the one-way slab is cylindrical.

- One way concrete slab bends or deflects in a direction perpendicular to the supporting edges

- Slab panel is supported in the short direction of one-way slab on two opposite sides

- The thickness of the one-way slab varies between 100mm to 150mm based on the deflection consideration and span