In most construction projects, the planned project completion date cannot be met due to unexpected delays that hadn’t been planned before the project start. Those delays can be considered excusable if they are attributable to the Employer, but not if they are attributable to the Contractor. To avoid the imposition of Liquidated Damages on the Contractor, the Contractor must demonstrate his right to an Extension of Time for Completion by proving that the dominant delays are excusable. There are different delay analysis methodologies available for analyzing project delays and quantifying the entitlement to an Extension of Time for Completion.

What Is Time Impact Analysis(TIA)?

According to AACE, the Time Impact Analysis (TIA) method is one of the most reliable approaches for analyzing and quantifying the entitlement for the Extension of Time for Completion during the project. It is advised that the TIA method is used in a “forward looking” or “prospective analysis” approach.

A Time Impact Analysis (TIA) is a time-estimating technique that demonstrates the cause and effect of a change to a CPM (critical path method) time schedule. The aim of a Time Impact Analysis is to identify a discrete issue and determine its relationship to activities or past delays in order to substantiate the impact a delay may have on a project time schedule.

Time Impact Analysis (TIA) is an approach to analyze delays on a project. You have to develop a fragnet, which is a fragmentary network for the issue (i.e. the change). It’s like a mini-schedule for the change. You take that fragmentary network, you drop it into a contemporaneous schedule, and then look to see how it affects that schedule. That’s the Time Impact Analysis.

A Time Impact Analysis is a method used to determine the extent of impact from potential delays in the construction works. This Time impact analysis involves adding new activities indicating changes or delays into an updated schedule representing progress up to the point when a delay event occurred to determine the impact of those delayed activities

A time impact analysis is a method used to determine the extent of the impact that change order or delay will have on the overall project schedule. This is a “forward-looking” analysis since it focuses on the impact of events that have already occurred or are presently occurring.

TIA will be most effective for projects using the CPM (critical path method) for scheduling. The time impact analysis (TIA) focuses on a specific event, by providing a snapshot of the impact event & integrating it into the project’s current critical path.

When to use the Time Impact Analysis Method?

The Time Impact Analysis method can be used in both prospective (forward-looking) and retrospective (retrospective or forensic) delay analyses.

For prospective delay analysis, TIA is often the preferred method. Indeed, the United States government revised its standard scheduling specification in 2015 to require the use of the Time Impact Analysis method for prospective (forward-looking) analyses.

The Time Impact Analysis method works best in forward-looking (prospective) delay analyses because the viability of a TIA diminishes as more time passes between the identification of a delay/change and the preparation/approval of the TIA. When a significant time has elapsed, an owner may believe that unrelated contractor-caused delays have diluted the effects of the owner’s delays.

As the impact of the prospective TIA is absorbed into the project record/actual data, the value of the findings of the prospective TIA diminishes to the point where a more thorough forensic analysis is more appropriate. For these reasons, it is critical that prospective TIAs are prepared and reviewed immediately following the identification of a change or delay.

Types of Delays

There are two main types of delay:

- Excusable Delays

- Non-Excusable Delays

Excusable delays occur when the affected party is allowed to claim for an extension of time, compensation, or both. Meanwhile, non-excusable delays are delays that the main contractor/subcontractor or the affected party needs to bear responsibility.

General steps for performing a Time Impact Analysis

- Analyze the Contract

- Reviewing and validating /compiling an as-planned schedule

- Insert fragnet of activities representing delays into a reasonable as-planned schedule

- A constructability review of the impacted schedule

- Identify variances between planned & impacted schedules

- Causation analysis

- Identification, quantification & apportionment

How to Perform TIA in Construction (Time Impact Analysis)

Properly performing a TIA (time impact analysis) requires attention to detail and sometimes can be time-consuming, but it will produce the most precise results. Read below an overview of how a true time impact analysis works.

1-Identify the Impact Events

Impact events can be change orders, delays, or any other event that may impact the overall project finish date. The first step is to collect the documentation & identify what additional activities are required to correct the impact. This should show the sequence of activities & time it will take to finish the additional work required.

This is often called creating a “fragnet” (short for “fragmented network”). Consider a fragnet a miniature CPM schedule for whatever is impacting the project time schedule. By identifying how the change will be undertaken, it’s easy to determine how much time the change will take, and how that change will affect the overall time schedule.

2-Identify the Current Project Time Schedule

Project time schedules are changing all the time. Select the most current time schedule available. The TIA will fail if using an outdated version of the time schedule.

3-Add the New Activities to the Time Schedule and Analyze the Impact

The next step is to plug the fragnet into the project time schedule. Again, “fragnet” simply refers to the mini-critical path which represents what work is required due to the event that’s changing the project time schedule. Basically, it’s just a mini-programme for the new work.

This requires identifying any logical relationship sequence between activities. If one task will depend on some other task first being completed, that should be noted. Once the fragnet is correctly inserted into the time schedule, be sure that the activities still follow a logical path. If there are any scheduling issues, make any necessary adjustments, and document the changes.

4-Recalculate the Critical Path

Finally, you can analyze what sort of impact the event had on the overall project schedule. Determine whether the event had any impact on the critical path or any interim milestones. Compare the original time schedule to the impacted time schedule to determine if and how long the contract finish date has been affected.

How to Perform TIA in Construction (Time Impact Analysis) in practical way

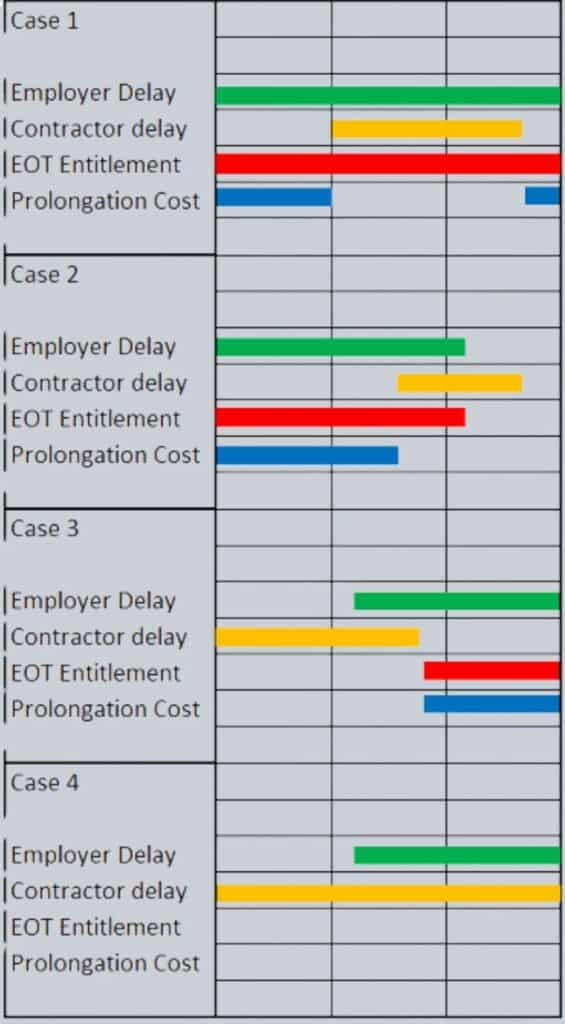

The TIA approach has the advantage of being a dynamic method that indicates the state of the project at the time of the delay. As a result, the concurrent delays can be viewed in order to calculate the correct entitlement for EOT for the Contractor; if those concurrent delays were attributable to the Contractor and overlapped with the Employer’s delays, those delays periods shall be deducted from the Contractor’s entitlement, as shown in figure 1.

1.To begin performing the TIA on a delay event, the forensic planner (delay analyst) must first identify the fragnets to be included in the schedule, which can be accomplished by collecting all correspondence, RFIs, VORs, and so on connected to that delay event.

2.It is essential to use an approved or agreed-upon program to insert the fragnets. The next stage in executing the TIA is to select the appropriate updated program for progression. This is one of the most essential steps in the TIA since it depends on the type of delay, whether it is due to additional work, a change in the type of materials, a different installation method, the employer suspending work, and so on.

3.To choose the right updated programme for progress, the delay analyst must first determine the delay start date, and then choose the most recently updated programme for progress prior to the delay start. If there was an activity in the P6 Programme for getting instructions to begin work in a specific area, obtaining the IFC designs, or receiving materials delivered by the Employer, the delay start date will be that activity’s late start date.

4.If you receive an instruction to modify the type of material, then verify the late dates for the activities associated with that material (Engineering, Procurement, and Installation), then check the date of instruction. If the date of instruction is earlier than the dates of those actions, there is no need to perform the TIA because there would be no time impact from the delay event. If the date of instruction is later than the late dates of those activities, the delay analyst must select the most recently updated programme for progress prior to the late start of those activities.

5.After selecting a suitable updated programme for progress, make two copies of it and rename one “before impact” and the other “after impact.” Incorporate the prepared fragnets into the “after impact” program and link them to the impacted activities. Create a new activity code, rename it with the delay event, and assign it to the fragnets and impacted activities. Run the program, then analyze the new longest path, assign that activity code to the activities on the new longest path, and then assign the “before impact” program as a baseline to the “after impact” program. Using the “used activity code” filter, compare the two programs on the impacted path to see the impact of the delay on the impacted activities.

6.After performing those analyses, the delay analyst now has the expected impact from that delay. The delay analyst also needs to transfer the “used activity code” and check the longest path in the “before impact” program, view the actual delay until the data date of that program, and check if the impacted activities filtered by “used activity code” are on that longest path to justify that delay. If the impacted activities are not on the shortest path, the delay analyst must attempt to link the delay in the “before impact” program to another delay event produced by the Employer in order to avoid deducting the delay period induced by the “after impact” program. If he can’t find a reason for the delay or relate it to the Employer’s delays, the overlapped duration between the two delay paths will be deducted from the delay period resulting from the “after impact” program.

7.Excusable delays are classified into two types: compensable and non-compensable. Excusable compensable delays are those where there is no overlap between the Employer’s delays and the Contractor’s delays, which means it is only for the period of the Employer’s delays, whereas excusable non compensable delays are those where there are delays from both sides in that period, as shown in figure 1. Excusable non-compensable delays may also be defined by the Employer as delays that are beyond his control, such as weather changes, material shortages, and labor strikes.

Recommended Resources

Consultant Requirement for EOT Claim

High-rise towers EOT Claim (XER + Narrative)

Residential Project EOT Claim (XER + Narrative)

See Also

Delay Analysis For Construction Project

EOT Claim Preparation (Delay Analysis)