RCC framed structures are currently very popular for nearly all building types. Slabs, beams, columns, and foundations are the key building/house sections that provide the power to stay undisturbed and provide power for good performance during the lifetime. We speak here about the two ways. One should know the slab before you understand the one-way slab or the two-way slab.

The slab is a flat fundamental component of any building/house that can be used for floors and roofs. It usually consists of reinforced concrete. Slabs are the structural elements most commonly used whose thicknesses are significantly smaller than their other dimensions. Slabs can have different shapes and conditions of support. It may be solid, waffle-types, ribbed. They are categorized as one-way or two-way slabs according to their load-carrying behavior.

The one-way slab is a slab supported by parallel walls or beams with a length to width ratio equal to or greater than two and bends only in one direction during the transfer of loads to the walls or beams.

Read More about One Way Slab

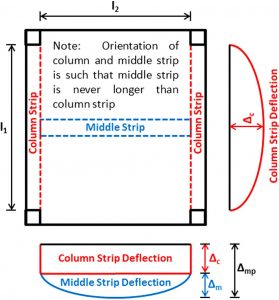

Deflection in Two Way Slab

The two-ways slab deflects under the force of loads in a plate or saucer-like shape. Corners of the two way slab lift up if the slab is not cast monolithically with the supports (walls/beams).

Even the slab supporting on three or two adjacent edges can also be seen as a two-way slab. In this situation, loads are divided into two directions depending on the ratio of the side.

The main bars are provided in two-way slabs in both directions and are perpendicular to each other.

If the corner of the simply supported two-way slab isn’t held down, the support is tended to be lifted and negative moments arise. The corner reinforcement (torsional reinforcement) should, therefore, be made available at a discontinuous edge of the two-way slab.

Depending on the span of these slabs, their usual thickness is between 100 and 200 mm. the two-way slab is suitable for panel sizes up to six m x 6 m. The panel is economical.

Depth of Two Way Slab

The minimum depth of the two-way slab, deflection criteria are most often applied. Sometimes the minimum depth can be sufficient according to the bending model, but if deflection requirements are not met, vibrations occur even for small loads such as walking, jumping, etc. So even design checks can give you less depth, checking for deflection always. You can provide a slightly large depth here and also save steel. The vibrations do not give occupants a sense of safety.

Types of Design For Two Way Slabs

1-Two Way Solid Slab With Beams

The slab is supported by beams in a two-way solid slab system. It can be designed for a wide variety of load conditions depending on the beam and column arrangements.

2-Two Way Waffle Slab With Beams

For office buildings (low rise), parking structures, and warehouses, a two-way waffle slab system is used.

3- Two-way Waffle Slab (with Integral Beams)

The two-way waffle slab is provided with a bigger span as compared to the solid slab. The two-way waffle slab is economical when it is used in the modular or prefabricated form.

4-Two-way Slab with the Hollow Block

Two-way slab action is assumed in a ribbed floor made of the double-tee section (precast), in the ribbed floor with integral beams, and also in hollow-block or hollow-cored slabs.

5-Two-way Flat Slabs

The two-way flat slabs are more suitable for the bigger loads, and spans compare to the flat plates. It is because of the drop panels or/and column capitals that provide higher shear and flexural strength. Thus flat slabs are used for heavier loading & longer span. It requires less concrete, and reinforcement compared to flat plates. However, they need more formwork for capital and panels and take more time to construct than the flat plate. They are used in spans that are square or nearly square. Flat slabs may be used for span up to 10m & imposed loads up to 7 KN/m2

See Also

Types of Walls in Construction

Types of Bonds in Construction