Contractors are frequently interested in a custom construction project’s cabinet shop drawing work. Have you ever considered why these cabinet shop drawings are so important? Let’s dig a little deeper.

What is a cabinet shop drawing?

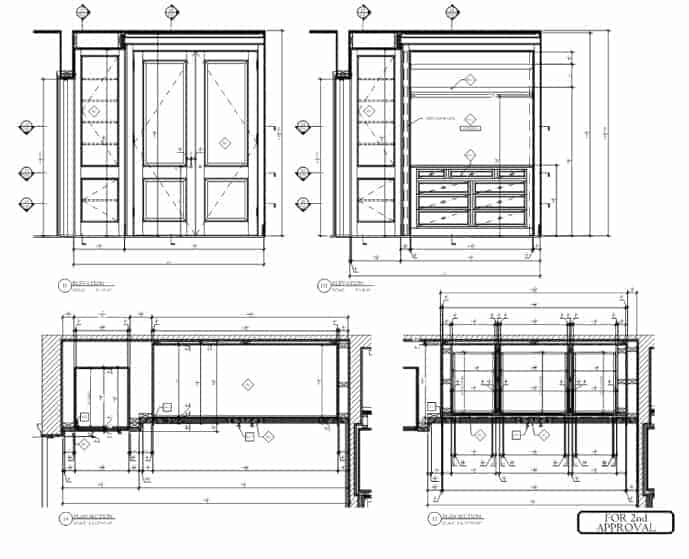

A cabinet shop drawing is a detailed sketch that represents the assembly of casework and includes information such as material, dimension and scale, and installation instructions, among other things.

Casework or cabinet detail drawings are built into buildings or structures and require careful attention to all of the information included in shop drawings.

As the name says, cabinet shop drawings involve the creation of boxed furniture parts such as storage areas, bookcases, cabinets (display and storage), drawers, shelves, and so on. It is the process of assembling box-shaped furniture.

The most important element of casework is modularity; in other words, the components—and, by extension, the end products—are usually used for modular purposes.

Cabinet shop drawing is the set of assembled parts that make up an entire cabinet (or other furniture pieces), as well as the methods used to keep such parts safely assembled. While the phrase “Casework” is most commonly used to refer to commercial-grade cabinetry, it can also refer to any cabinet that takes a variety of materials requirements to build.

What is the Importance of Cabinet Shop Drawings?

Design engineers require casework shop drawings or cabinet shop drawings for creating furniture in the form of visual illustration, just as architects require architectural blueprints.

Booths, doors, benches, windows, display racks, kitchen/food preparation countertops, kitchen cabinetry, display cabinets, mantelpieces, and other essential interior elements are examples of millwork and casework objects that require drafting and detailing attention.

The primary purpose of cabinet section drawings is to provide a visual representation of the boxed furniture’s components. In this case, the parts are prefabricated and must be assembled on-site to complete the finished product.

The act of deciding on a uniform standard for the sake of consistency is merely the first step toward generating a functional and coherent casework shop drawing.

Engineers, architects, interior design firms, and general contractors should analyze the manufacturer’s version of the casework before placing an order, which is one of the primary functions of a casework shop drawing.

All project stakeholders, including CAD drafters, furniture designers, architects, casework makers, and clients, must continue to collaborate in order to develop shop designs into something usable for the project.

Advantages of Cabinet Shop Drawings

1. Conflict/Clash Analysis

The level of detail and annotation on architectural plans for a larger project with multiple architects can vary. The good news is that a simple shop drawing will help in resolving the discrepancies.

Cabinet Shop drawings are essential for resolving design disputes even during the design stage. Detailed cabinet shop drawings with important information and annotations can assist architects in aligning their architectural plans.

Drafters utilize their experience and creativity to interpret detailed architectural plans and create extensive shop drawings for cabinets. When several architects collaborate on a project later in the process, their designs may differ in detail, but cabinet or millwork shop drawings may help to overcome these differences.

Cabinet shop drawings essentially settle design-stage disputes between contractors, architects, and manufacturers. Accurate cabinet section drawings, ideally, help architects align design and measurements with their architectural plans. It is possible to detect errors or conflicts caused by tolerance or geometrical limits issues early on.

Wall-mounted cabinets are the most important in terms of measurements. This is because they fit into the alcoves of the walls, necessitating precise manufacturing while maintaining the overall aesthetics of the room. As a result, producing precise and error-free cabinet shop drawings is essential.

3. Precise Details and Specifications

Shop drawings are extremely accurate and detailed, and it’s easy to fall into the trap of cramming as many specifics into a shop drawing as possible in the hopes of making it more understandable. Many casework drafters enjoy depicting every dowel in minute detail.

Overloaded drawings become clumsy to manage and make extracting details quickly difficult. On the other hand, extra documentation might be unnecessary at times because an abundance of data can lead to uncertainty and, worse, misinterpretation.

As a result, drafters should leave out any unnecessary details in the sketches to save time for all project teams. Repetitive information should be removed so that all project participants can access and understand the shop drawing. The exclusion, on the other hand, must be agreed upon. Before creating another shop drawing, it is critical to select a suitable format.

Designers or CAD drafters must have enough information to ensure that the information is delivered on time. To standardize the process of casework or millwork furniture design communication and manufacturing details, standards such as AWI, NBKA, NFC, or any other convenient standard are used.

The shop drawings created by drafting teams who adhere to these guidelines ensure consistency across organizations and platforms.

3. Budget Plan

The advancement of parametric CAD features has made creating shop drawings easier and adding more data to the drawings less stressful for CAD drafters. Furthermore, as design coordination between architects and developers improves, manufacturing quality improves as well, thanks to detailed cabinet shop drawings.

The annotations for the change are easily accessible, allowing for a faster approval process. Error detection during the design stage eliminates the need for mark-ups and rework. Finally, this allows the project to be completed on time; the sooner it is completed, the less expensive it is.

Cabinet shop drawings also allow for any last-minute changes, such as material substitutions or design improvements, to be noted and later revised. These approved mark-up drawings are critical for checking an internal request and resulting in favorable decision-making with ready-to-use data.

4. Understanding the Art of Detailing

Cabinet shop drawings should be detailed enough to show the architect the exact product structure as well as the construction methods. Nonetheless, many millwork companies believe in incorporating intricate millwork details into every single dowel and screw location.

However, having extra information is also a problem because it makes the shop drawings appear crowded and confusing, which leads to a series of errors and missing important details during manufacturing. It has been observed in the architectural community that, with the exception of a few, many architects do not place a high value on such details.

Aside from the cabinet shop drawings job, it is not recommended to spend too much time detailing the micro things that aren’t in your scope unless you believe it is absolutely necessary for the project. We’ve often seen designers include the same window replicating itself on a single wall alongside the cabinets.

Conclusion

Good drawings are required for success in the custom cabinet/architectural millwork industry. They provide a clear representation of a project to both the client and the cabinetmakers who actually do the work.